All sterile medical devices require validation of their packaging. The sterile barrier must be shown to be effective throughout the product's claimed shelf-life, and this is demonstrated through medical packaging seal strength and integrity testing. Examination of materials, processes, and stability all contribute to demonstrating that the sterilisation process is effective and that sterility is maintained.

The key standard for this process is ISO 11607-1 - Packaging for terminally sterilized medical devices - Part 1: Requirements for materials, sterile barrier systems and packaging systems. It is concerned with the design, materials, equipment, and effectiveness of seals or welds. The complete packaging system, including boxing, is covered during medical packaging seal strength testing. The requirements apply equally to terminally sterilised medical devices and to those produced aseptically.

Methods and standards we follow during medical packaging seal strength testing include:

-

ASTM F1886/F1886M:

- External visual inspection, a relatively simple test that we routinely use to supplement information gleaned from other seal tests.

-

ASTM F2054/F2054M or ASTM F1140:

- Burst test, a good strength test that assesses the entire seal area, locating the weakest point. Suitable for both porous and non-porous packs.

-

ASTM F88/F88M or EN 868-5:

- Seal tensile peel test.

-

ASTM F1929:

- Dye penetration test where dye is injected into sealed packs and ingress into seals is then inspected visually. Suitable for packs with at least one transparent web.

-

ASTM D3078 or ASTM F2096:

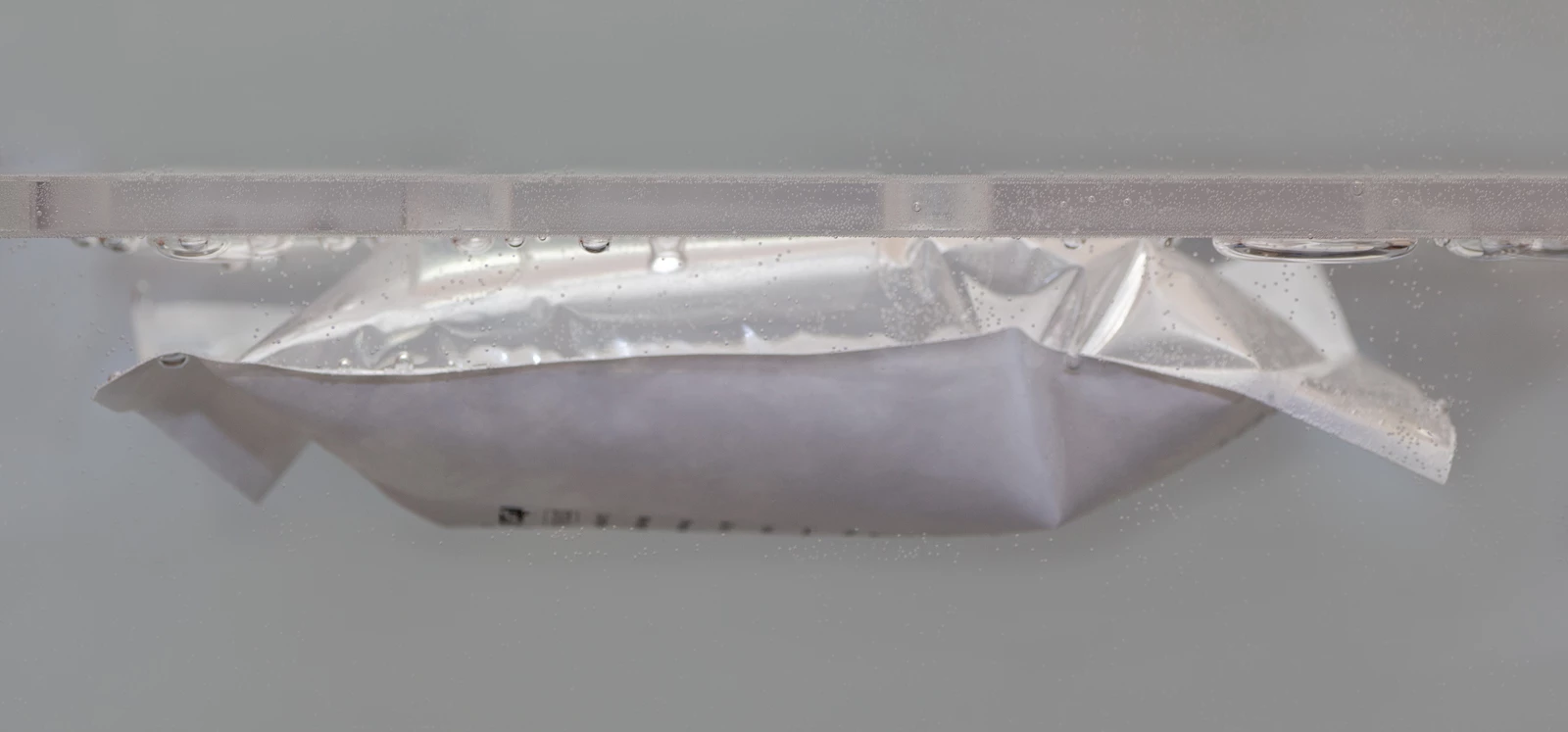

- Bubble emission, a vacuum test for non-permeable packs.

- Hospital environment microbial aerosol test - This test has been validated internally and shown to find channels as small as 0.3mm (no attempt has been made to validate below this). It simulates 1 year of storage, unprotected, on a hospital trolley.

- Liquid immersion test - requires sterile packs.