Protect Patient Safety and Ensure Regulatory Compliance: Partner with MET for Medical Device Packaging Testing

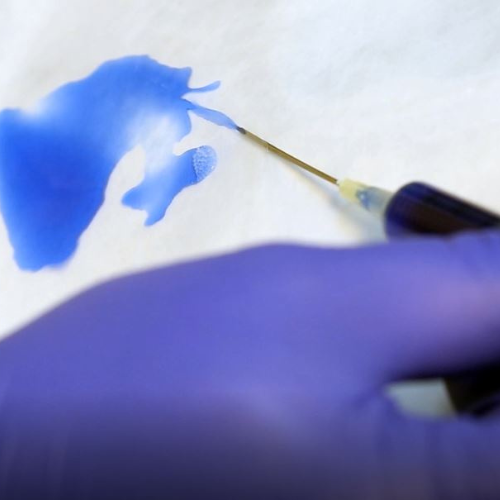

Packaging forms an integral and very important part of all sterile medical devices. CE technical files and FDA submissions both require testing to ISO 11607-1: Packaging for terminally sterilized medical devices. This is why medical device packaging testing is so important.

Ensure your medical devices arrive sterile and functional with MET's comprehensive packaging testing. We support engineers in validating pharmaceutical containers, medical pouches, and blisters for all device classes.

Our Expertise, Your Confidence:

- ISO/IEC 17025 Accredited Lab: Unmatched accuracy and reliability.

- Calibrated Accelerated Ageing Chambers: Simulate real-world aging for validated shelf-life claims.

- Rigorous Testing Equipment: Assess burst strength, leak resistance, and tensile integrity.

- Transit Simulation Studies: Optimise your shipping containers for ultimate protection.

MET hosted a Live Free Webinar on Transit Testing for Medical Device Packaging, Download the transit validation webinar free here

Ready to simplify packaging validation? Learn more about our services below.

Accelerated Ageing & Real Time Ageing

Accelerated aging is used to simulate real-time shelf-life aging and is, therefore, conducted to validate shelf-life claims. While accelerated aging offers insights, real-time aging studies may be conducted to further confirm long-term stability. This testing is carried out according to ASTM F1980 - Standard Guide for Accelerated Aging of Sterile Medical Device Packages. Combined with other testing, such as functional, transit, and packaging, ageing can give you a long term view of your products and packages. Read more about Accelerated Ageing

Seal Strength & Integrity

Including ASTM F2054 for Burst Testing with restraining plates, F2096 for Bubble Emission Testing, and F88(M) for Seal Tensile Peel testing, MET can evaluate the package integrity and seal strength. All sterile medical devices require validation of their packaging. The sterile barrier must be shown to be effective throughout the product's claimed shelf-life. Examination of materials, processes and stability all contribute to demonstrating that the sterilisation process is effective and that sterility is maintained, and that the sealing process is viable and consistent, with batch testing and aging validation studies. Read more about Seal Strength and Integrity

Transit Simulation

Shipping validation is mandatory for CE marked medical devices. MET's testing protocols follow the philosophy of ISO 11607-1 - Packaging for terminally sterilized medical devices. Requirements for materials, sterile barrier systems and packaging systems. We offer a variety of ISO11607-1 approved and FDA recognised testing standards including ASTM D4169 and ASTM D7386, and various conditioning parameters all dependant on your needs and shipping requirements. Read more about Transit Simulation

Why Choose MET

- 25+ Years of Specialised Focus: We don't just test, we understand the unique challenges of medical device packaging.

- State-of-the-Art Facilities: Cutting-edge equipment delivers precise results you can trust.

- Expert Team: Our highly trained staff provide insights, not just data, to guide packaging success.

Ready to safeguard your devices and your reputation? Contact MET for a personalized testing plan. +44 (0) 1304 213223