Extractables and Leachables Testing is an analysis of potentially harmful materials that could be administered to a patient with a drug or device. Pharmaceutical manufacturers use laboratories to assess whether chemicals are transferring into the drug from packaging or production. Medical device companies use it to show that materials of concern are not transferred from the device to the patient.

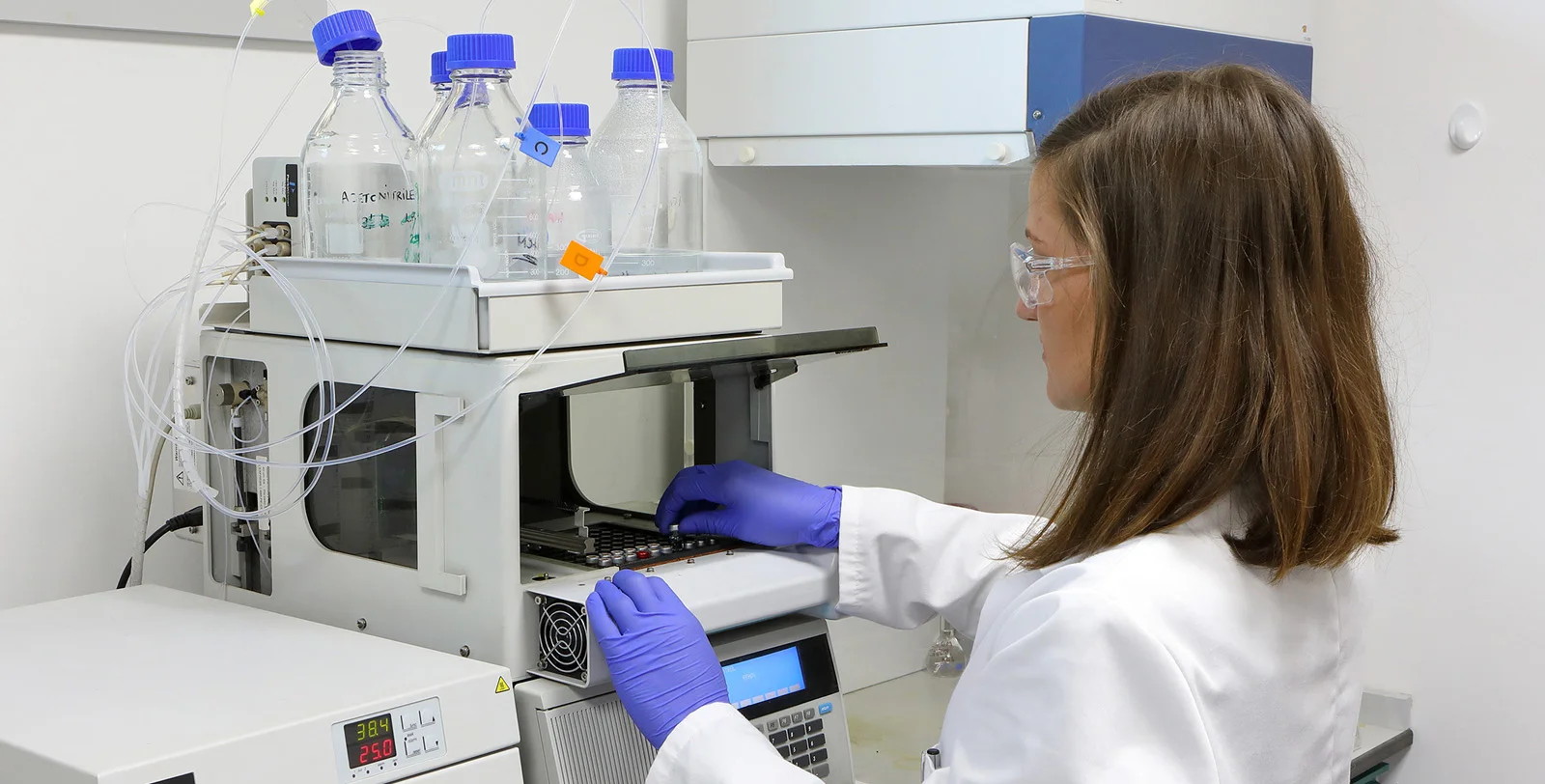

Commonly applied analyses look for very low concentrations of chemicals. These methods include atomic absorption spectroscopy (for metals) as well as gas (for volatile materials) and liquid chromatography (for non-volatile chemicals) followed by mass spectroscopic analysis to identify the materials.

Pharmaceutical Container Closure Systems (CCS), drug delivery devices, and medical devices should all be tested for the availability of extractables and leachables. The nature of the substances should also be analysed. Toxicological assessments may then be made, to quantify a patient's exposure to each chemical and gauge the level of risk posed by these materials.

The FDA provides a definition of the terms:

Extractables – Compounds that can be extracted from the container closure system when in the presence of a solvent

Leachables – Compounds that leach into the drug product formulation from the container closure as a result of direct contact with the formulation

In the pharmaceutical setting, migration of chemicals from all components of the packaging system should be considered: the primary and secondary containers, sealing materials, labelling adhesives, and inks. Materials from processing systems can also find their way into formulations. In some cases, it is not only the toxicity of these substances that is of concern. They can influence the stability of APIs, particularly biologics.

In the case of combination devices and medical devices, ISO 10993-18 is the primary source of regulatory information. For combination products, such as pre-filled syringes or skin patches, the storage time must be taken into account. For surface devices, extractable and leachable testing is sufficient. However, for implant devices, degradation studies, as detailed in other parts of ISO 10993 (parts 13, 14 and 15), are required.

MET delivers a wide variety of analytical techniques in order to identify organic and inorganic substances (metals, volatiles, non-volatiles). We work to ISO, USP and EP standards and methods. We can also combine this testing with performance and sterility testing to provide complete design validation for your products.

MET is providing six service levels for materials characterisation according to the invasiveness of your device’s body contact. There are two levels for pharmaceutical containers, three levels for medical devices, and a special level for breathing circuits.

Level 1 - Medical Device Transient Contact

Is suitable for surface contacting devices with transient or short term use.

- Chemical data gathering

- Standard protocols

- Two extraction polarities (ISO 10993-12)

- Phthalate reference standard only

- ICP-MS, GC-MS, HPLC-DAD

Level 2 - Medical Device Prolonged or Invasive Contact

Is suitable for medium risk devices.

- Chemical data gathering

- Brief material review and method verification

- Standard protocols

- Two extraction polarities (ISO 10993-12)

- Phthalate reference standard, plus any standards referenced in quote

- ICP-MS, GC-MS, HPLC-DAD

- Optional Toxicological Risk Analysis

Level 3 - Medical Device Permanent Contact

Is suitable for implant and repeat use devices.

- Gathering of chemical data to include materials and manufacturing processes.

- Material review and risk analysis with method verification

- Specific study design and protocol using validated methods

- Method development if required

- Comparative reference standards for chemical identified in the initial review of the available data

- Three extraction polarities, exhaustive or special extraction, sample concentration (ISO 10993-12)

- Analysis of extracts (ICP-MS/AAF, HeadSpace GC-MS, GC-MS, LC-MS, LC-DAD)

- Toxicological Risk Analysis

Level 4 - Pharmaceutical Container and Process Equipment

Is suitable for low risk pharmaceutical products.

- Gathering of chemical data to include materials and manufacturing processes.

- Thorough material risk analysis

- Collaborative study design

- Detailed protocol with rationale for test methods and extraction ratios.

- Method validation.

- Includes comparative standards for all materials of concern

- Three extraction polarities, sample concentration

- Leachables analysis

- ICP-MS/AAF, HeadSpace GC-MS, GC-MS, LC-MS, LC-DAD.

Level 5 - Pharmaceutical Container and Process Equipment

Is suitable for high risk methods of delivery: intravascular, ophthalmic and chronic use pharmaceutical products.

- Gathering of chemical data to include materials and manufacturing processes.

- Thorough material risk analysis

- Collaborative study design

- Detailed protocol with rationale for test methods and extraction ratios.

- Method development

- Method validation

- Includes comparative standards for all materials of concern identified

- Three extraction polarities, sample concentration

- Leachables analysis

- ICP-MS/AAF, HeadSpace GC-MS, GC-MS, LC-MS, LC-TOF, LC-DAD.

Read more about extractables and leachables here.